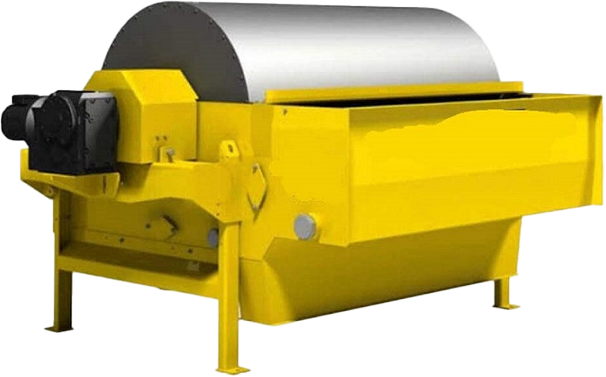

Wet magnetic drum separators for ore enrichment are preferred in applications where liquid fluid dominates the process. The material is fed to the drum separator through the feeder, the material with magnetic sensitivity is affected by the magnetic field of the drum and clings to the drum surface, and the magnetic minerals are separated through the system by magnetic polarization along the direction of rotation of the drum. Since non-magnetic materials are not captured by the drum, they are thrown out of the waste part of the separator from the output collector. At the end of the system, magnetic material is extracted from the desired product flow to increase product purity and plant productivity. In this way, the quality of the concentrate is maintained during the ore enrichment and the leaks that may occur are prevented. It is especially effectively used in the recovery of magnetite used as a heavy ambient liquid in coal mines.

Wet magnetic drum separators have straight and reverse flow variations.