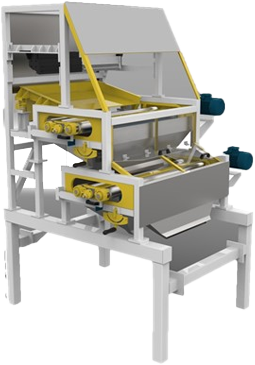

Roll magnetic separators are used in applications where fine grain size precision magnetic screening and enrichment are required.

The thin-sized moisture-free material, which has been passed through a mechanical process, is distributed uniformly on the tape on the separator with the help of a feeding hopper. The conveyor belt acts on a magnetic and non-magnetic roller. When the product moving on the conveyor belt arrives on the magnetic roller, the non-magnetic particles are ejected with the help of centrifugal force and separated into a non-magnetic material smash. The ferromagnetic materials continue to be transported on the tape by the magnetic force of the roll with the magnetic roller and are transferred to the other shot and the materials are separated.

Magnetic separators with high field strength are used especially in the enrichment and use of ores with weak magnetic properties. Roll Magnetic Separator is used for deceleration and enrichment of low magnetic susceptibility materials with a grain size between 500 microns and 5 mm