The most powerful magnetic product so far is the rare earth magnet. The most commonly used rare earth magnet is Neodymium. The alloy of the magnet contains boron and iron. A rare earth magnet with many advantages is preferred in most industries.

Characteristics of Neodymium Magnets

- They have the maximum magnetic energy field.

- It has maximum coercive forces.

- They have a maximum residual magnetism.

- For 10 years, only 1% of the magnetic energy is lost.

- It has high corrosion resistance.

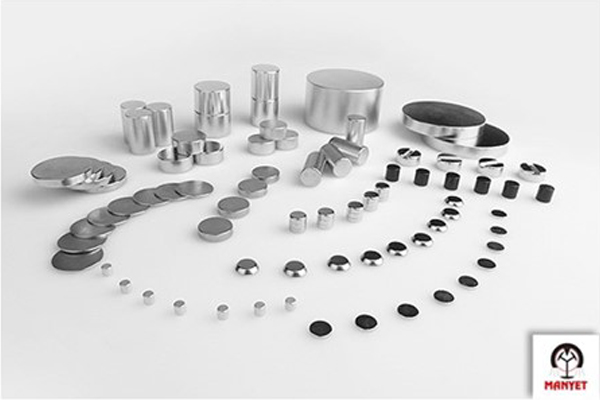

- In any way (disk, ring, segment, rod, etc.) they can be produced.

- In the industrial world, the need for magnets of very different shapes and sizes is formed. Neodymium magnets can be produced in desired shapes and sizes according to needs.